5.1 Our environmental management

In 2021, Madrileña Red de Gas has focused its environmental efforts on Integrated Management System Certification, and on obtaining carbon footprint verifications for 2020 (scopes 1 and 2) and the 2020 Sustainability Report according to GRI (Global Reporting Initiative) standards.

As well as achieving said verifications, we renewed certifications of our Integrated Management System (IMS) in Prevention, Environment and Quality, in accordance with the ISO 45001, ISO 14001 and ISO 9001 standards, respectively. We also continue to advance in improving how our processes, documents and records are managed by digitalising them through the IMS process management tool.

With the aim of supporting application of the Environmental Policy, the MRG senior management undertakes to provide the material, technical, economic and human resources to implement and maintain an Environmental Management System according to the UNE-EN ISO 14001:2015 and publicly declares the following principles and commitments:

- Alignment with higher environmental ideals and values.

- Firm commitment to complying with current legislation and other requirements that the organisation subscribes to.

- Efficient and sustainable management in the consumption of resources, promoting energy savings and minimising the use of dangerous substances.

- Pollution prevention and minimising the “environmental footprint” by controlling and progressively reducing the impact of our activities, by ensuring effective and appropriate management aimed at minimising waste and pollution, and by promoting measures to protect biodiversity and habitats.

- Apply environmental criteria in our relations and commitments with customers, suppliers and contractors.

- Implement environmental sustainability strategies for continual improvement.

- Promote internal activities concerned with raising environmental awareness and providing information and training on environmental issues.

- Strengthen environmental risk management, threats and opportunities.

Environmental objectives 2021

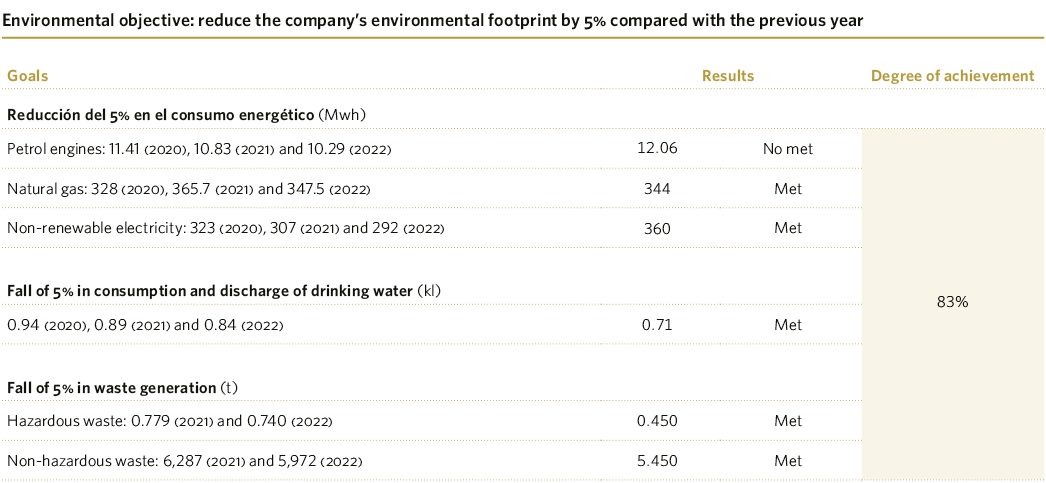

- One of the environmental objectives set in 2021 was to reduce the company’s environmental footprint by 5% compared with the previous year, with the following goals and results.

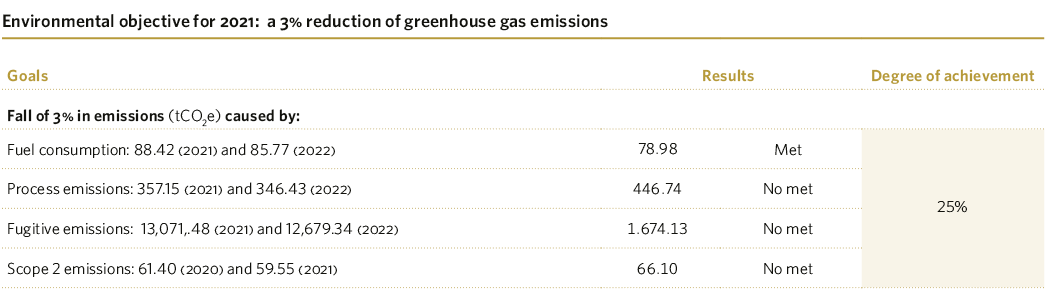

- The other environmental objective set for 2021 was a 3% reduction of greenhouse gas emissions, with the following goals set.

These objectives are aligned with the Global Real Estate Sustainability Benchmark (GRESB) and the 2015-2030 Sustainable Development Goals.

The company’s risk management policy involves progressively conducting cross-cutting analyses of the risks relating to the business and corporate units that are most closely linked to the processes involved. Within this context the environmental aspects are identified and assessed to determine which impacts may be significant.

The environmental aspects under study are those that can be controlled by Madrileña Red de Gas (direct aspects) and those over which MRG has no direct control of how they are managed, but can still have a degree of influence from a lifecycle perspective (indirect aspects).

They can be divided into the following areas of influence:

- Atmospheric emissions: from chimneys and other sources.

- Discharges: into sewers, pipelines, seepage, risk of leaks or accidental discharges, etc.

- Waste: generated in warehouses, regulation and metering stations, satellite plants, pipeline works, etc.

- Use of natural resources and energy sources: water, electric power, fuel, etc.

- Other environmental aspects: including aspects linked to nuisances such as noise, smells, etc.

Both the identification and the assessment of aspects are reviewed once a year, ensuring that the significant elements are under control and/or have the necessary actions in place for that purpose.

Suppliers assessed with environmental impacts

In 2021 work continued with the external service of standardising suppliers by assigning a control code to 51 critical suppliers, which means that how they evolve can be monitored.

Our process of standardising, selecting and monitoring suppliers ensure that our environmental commitments are transferred to them (as set out in detail in the chapter on our responsible supply chain management). In these processes, the necessary involvement and compliance with MRG’s environmental commitments are transferred through standardisation requirements and contracting. An IT system is used for contractor companies to record all management and certification requirements. This information is monitored periodically by MRG.

No environmental complaints have been recorded related to expansion works and technical services operations, or for any other activity conducted by MRG. No accidents with an environmental impact involving fines or civil liability were recorded in 2021.

Madrileña Red de Gas has an online service to identify and assess compliance with all environmental legislation that is applicable to its activities and facilities.

Dialogue with stakeholders

We carried out a range communication actions with our stakeholders in 2021 relating to the environment, including:

- The contaminated soils closing report was submitted to the relevant authority in the Region of Madrid and to several town councils in the Madrid region on the occasion of LPG plants being dismantled. Additionally, next year plans are in place to inform land owners of the conclusions to the administrative rulings issued in relation to this process.

- A response was sent to the request from the Spanish Gas Association (SEDIGAS) for information on methane emission estimates from the natural gas distribution network.

- Information report to the Directorate General for Industry of Madrid on the situation of LPG plants affected by Royal Decree 840/2015.

- Civil Protection notified of the Auto-Protection Plans in Royal Decree 393/2007 that remain operative, and which had previously been reported to the Directorate General for Industry of Madrid.

- The regional government of Madrid was informed of the estimates of fugitive methane emission from the distribution network in 2019 and 2020.

Building projects may also be subject to environmental impact processes that require involvement from the parties involved.

5.2 Our commitment in figures

The scorecard of process indicators allows us to identify the performance levels of the company’s critical or core processes, so that in the event of any deviations linked to risks or opportunities, the appropriate actions can be taken.

Environmental parameters are monitored annually, with each one shown along with a reference value established for the same period in the previous year. This objective view, in real time, makes it possible to define the courses of action to be taken within the company’s strategy.

5.2.1Consumption of resources

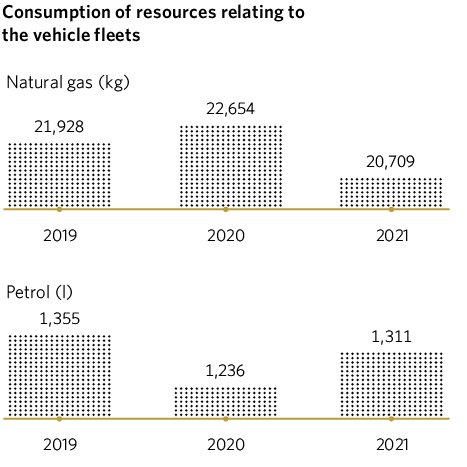

In 2021, 78% of the resource consumption indicators showed a positive trend, given that they were lower than the previous year’s figures.

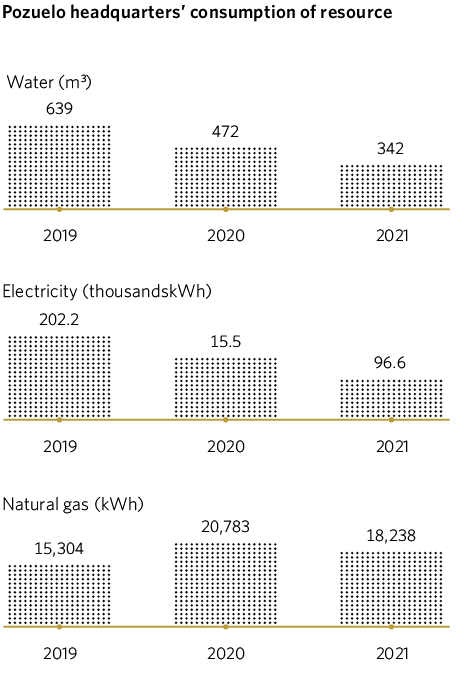

The consumption of resources in the building is on a clearly downward trend in each period, due to the measures adopted as part of the company’s strategy, which include fostering remote working and opening a new centre for operators, who are the staff members most in need of these resources.

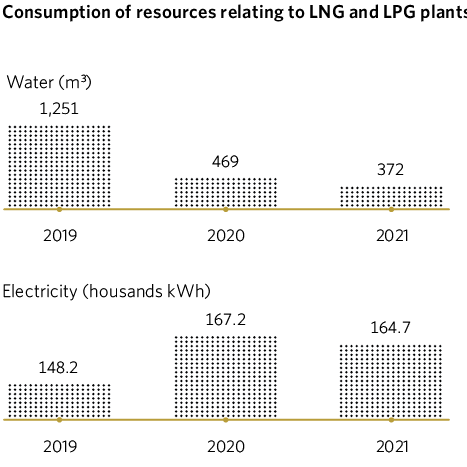

Except for the one-off increase in water consumption in one of our plants in 2019, the trend is one of lower consumption in recent periods. Water consumption in LPG plants is highly linked to the maintenance schedule and to the plants being dismantled, with regard to which it should be noted that water is used as part of the maintenance work and disassembly of LPG plants, as it is stored and reused in the same process for as long as the quality of the water allows it, thus minimising consumption while reducing the amount of contaminated water generated.

In terms of the reduction in natural gas consumption in the building, the impact on the pandemic led to a remote working model being adopted that requires much less use of offices, and the energy supply in 2022 is expected to be electrical only, by removing the changing rooms from the Pozuelo offices (the only source of natural gas consumption in the building).

It is true that digitalisation means a substantial and sustained drop in greenhouse gas emissions. The coronavirus pandemic has accelerated the digital transformation of our societies and highlighted the importance of digital technologies for Europe’s future economic growth.*

In this regard, we continue with the process of transforming to a PAPERLESS way of working, which began in 2017, and which includes the following measures that are currently in effect:

- Digitalise all field operations, designing mobility tools for operators which display necessary data for their work:

- Operations with customers: regular inspections, home operations, checking meters, etc.

- Network operations: maintenance (works, tracking leaks), emergencies, auxiliary facilities, etc.

- Network expansion works.

- Digitalise the company’s management processes: financial (invoices, payment documents, expense forms, etc.), network operations (works documentation, certifications, work orders, etc.), procurement (commercial contracts), human resources (payment, communications, etc.), risk management (audit documents, inspections, records, reports, etc.)

- Make work positions paperless.

- Change habits from working with paper: use of Google Drive for shared documents and work files, encourage the use of electronic resources, etc.

* European Commission press release, 2 March 2022.

5.2.2 Atmospheric emissions

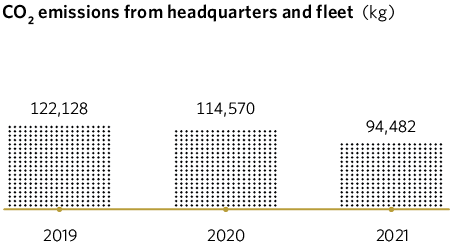

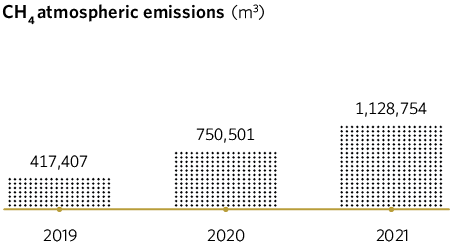

As mentioned previously, one of the goals in 2021 for Madrileña Red de Gas was to reduce greenhouse gas emissions by 3%.

These figures consider the building’s direct and indirect emissions. Fleet vehicles use petrol and natural gas for vehicles as fuel.

A drop in CO2 emissions was recorded with regard to previous years as a consequence of the fall in associated consumption levels.

This statistic does not include the petrol used in the vehicles use by sales staff, or employees’ own vehicles, which are sometimes used for company purposes.

Atmospheric emissions of CH4

Atmospheric emissions from the natural gas distribution network (scopes 1 and 3) are estimated using a specific procedure. Due to the complexity in the information gathered, this calculation is made once a year.

MRG has actively worked on developing and implementing a method to estimate fugitive emissions of CH4 from the gas distribution network based on events, which enables emissions to be calculated more realistically in comparison with the previous method by applying emission factors depending on what material the pipeline network is built from and the range of operating pressure in it, expressed as the off-gas flow per km of pipeline and per year.

Using this method, fugitive emissions of CH4 are independent from pipeline length. This takes into account the following:

- Intrinsic emissions (emissions from leaks due to holes or small cracks detected by tracking the network, due to permeation of the polyethylene and to leaks detected in regular inspections).

- Incidental emissions: due to leaks from damage, detected by company staff or by third parties, complaints or incidents, and communal or community leaks.

- Operational emissions.

The results obtained with this method are based on annual data that reflects the best practice applied to building and maintaining pipelines, and drawn from safety and environmental action plans carried out. The per-event method means that improvement methods can be applied that are of significant help in reducing methane emissions.

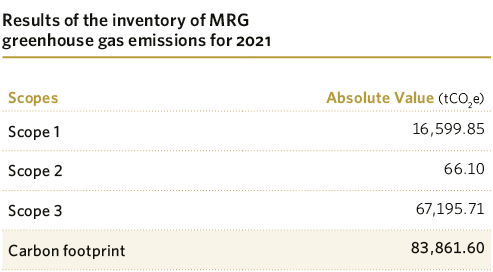

5.2.3 Carbon footprint, measuring and commitment

At the 26th United Nations Climate Change Conference, held from 31 October to 12 November in Glasgow, Scotland, new agreements were reached for market mechanisms, which basically supported transferring emission reductions between countries, while incentivising the private sector to invest in climate-friendly solutions.

In Spain, Royal Decree 163/2014, of 14 March, creating the register of carbon footprint, offsetting and carbon dioxide capture projects, seeks to raise awareness and incentivise society as a whole in combating climate change with the aim of bringing about a low-carbon economy, providing a response to the growing commitment that public and private entities alike have been showing in recent years in terms of reducing greenhouse gas emissions. To that end, a series of measures were established aimed at facilitating and encouraging the calculation of the carbon footprint, and reducing and offsetting it through CO2 capture.

In this framework, aware of how important combating climate change is to the company, we have strengthened our efforts to engage in activities aimed at reducing the carbon footprint of what we do. In 2020 Madrileña Red de Gas voluntarily calculated its carbon footprint, entering the information into the “section on carbon footprint and commitments to reduce greenhouse gas emissions” on the record of the Ministry for the Ecological Transition and the Demographic Challenge, after verification by an independent third party (Bureau Veritas), with the results validated in May 2021.

In 2021 work continued along the same lines.

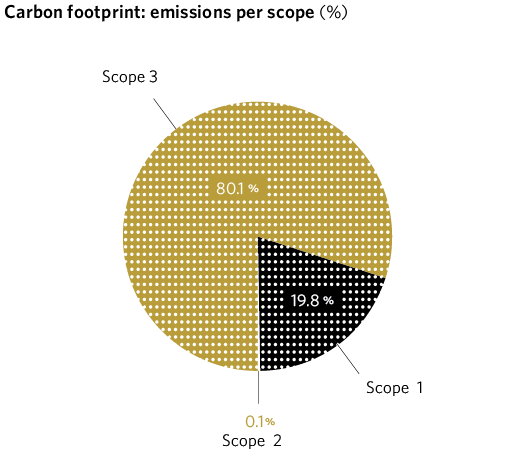

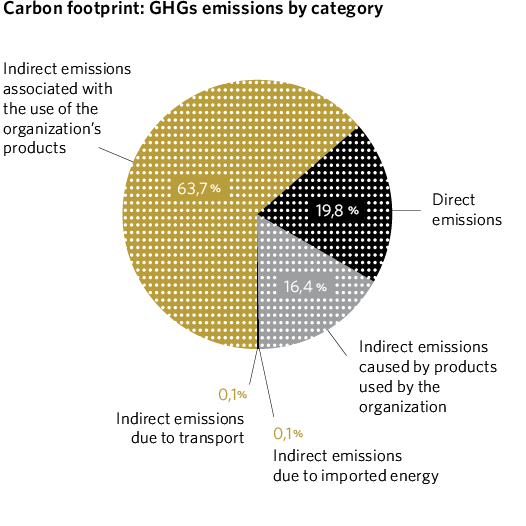

MRG has a specific tool and procedure that it uses to calculate its carbon footprint. The following sets out the types of sources of greenhouse gas emissions considered on the carbon footprint calculation for 2021:

- Scope 1. Direct emissions from greenhouse gases that belong to or are controlled by MRG.

- Scope 2. Indirect emissions of greenhouse gases resulting from the generation of electricity bought by MRG and which is not auto-generated. This therefore includes emissions from the generation of electricity acquired and consumed in and by MRG activities and infrastructure.

- Scope 3. Indirect emissions of greenhouse gases from sources that are not owned or controlled by MRG, but which are a consequence of the activities carried out and over which the company has some influence.

The changes introduced for 2021 were as follows:

- Incorporation of the scope 3 indirect emissions strategies.

- Transfer of emissions from leaks in communal receiving facilities from scope 1 to scope 3, with emissions from this source still being recorded.

With the expansion of indirect emissions, calculating the company’s carbon footprint is a help now more than ever in managing the risks and opportunities relating to greenhouse gases in a global and comprehensive way, so that the “carbon component” can be incorporated into decision-making processes.

The activities and infrastructures included in the carbon footprint scope are as follows:

- Central offices at C/ Virgilio, 2 [B] – Edif. 1. 28223 Pozuelo de Alarcón, Madrid (Spain) and warehouse unit at calle Valdemorillo, 60, 28925 Alcorcón, Madrid (Spain).

- Natural gas and LPG distribution network of the Region of Madrid.

- LNG plants and LPG plants belonging to the distribution network.

- Fleet vehicles.

How the full carbon footprint has evolved with regard to previous years will be analysed once two consecutive years have passed in which the same calculation method is used, so that comparable results are obtained.

Madrileña Red de Gas has defined certain courses of action on sustainable behaviour aimed at minimising greenhouse gases, which consist of:

Calculating the company’s carbon footprint is a help now more than ever in managing the risks and opportunities

- Appropriate management of fossil fuels and natural resources, energy saving and energy efficiency, and sustainable mobility.

- Foster the use of more efficient technologies among customers. Introduce energy-saving habits among customers.

- Help to disseminate and promote energy efficiency improvements for buildings.

- Ensure that value chain activities are developed in environmentally respectful ways.

5.2.4 Pojects and investments aimed at stimulating energy efficiency and reducing emissions

Mobility with green hydrogen in the Madrid region.

At Madrileña Red de Gas we show our support for social and environmental welfare through ongoing collaboration on sustainable projects, and we are clear that transport is the sector that generates a greater volume of greenhouse gases.

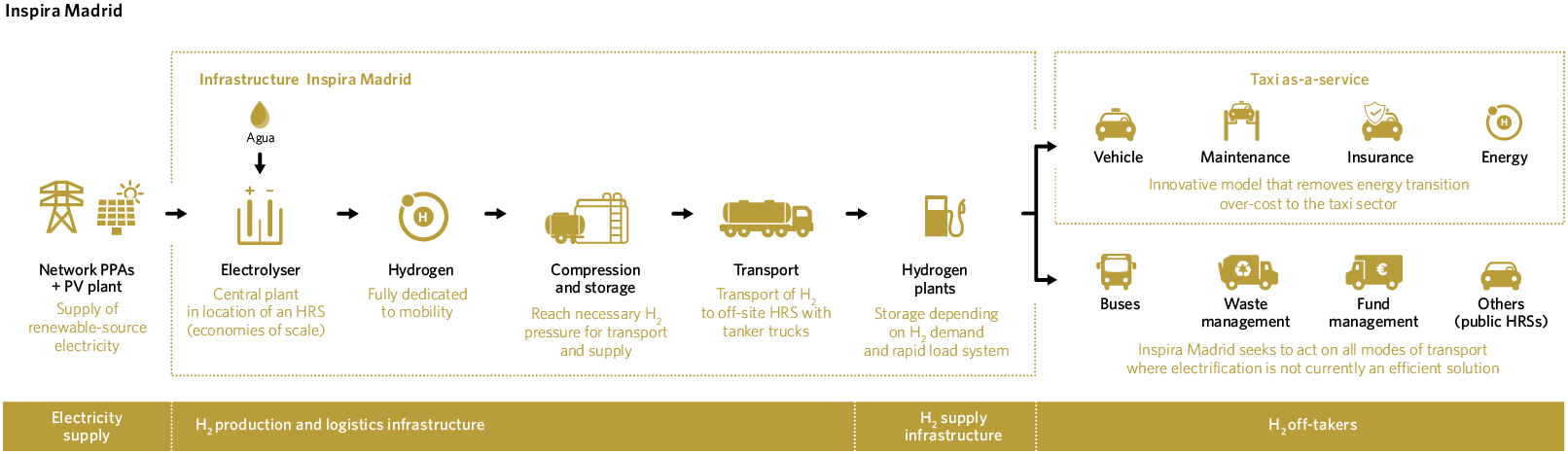

Together with the Professional Taxi Federation of the Region of Madrid (FPTM), FRV, Toyota España and the Ruiz Group, MRG is participating in “Inspira Madrid”, the most important green hydrogen mobility project currently in effect in the Region of Madrid. With the collaboration of PwC as strategic advisor, the aim is to be involved in the hydrogen value chain with the goal of decarbonising urban public transport fleets in Madrid, a unique project in this region.

CO2 y NOx emissions associated with transport and mobility, one of the largest environmental problems

Land transport in the Region of Madrid accounts for 55% of the region’s CO2 emissions, and is one of the main causes of polluting emissions. The project consists of deploying the infrastructure to produce and supply renewable hydrogen by means of a network of five public-access hydrogen plants (HRSs) in an initial phase which, when combined, will fuel light and heavy vehicles at a competitive price compared with conventional fossil fuels.

In all the project’s phases, “Inspira Madrid” actively collaborates with the various green hydrogen end users to guarantee demand for the hydrogen produced. These collaborations come with the strategic backing of the FPTM in terms of the sector’s progressive decarbonisation.

All of the region’s main forms of transport, of both people and goods, are represented in the project. In this context, work is ongoing with Toyota España to develop an innovative business model by which to implement a new hydrogen fuel-cell vehicle in the taxi sector. The project also includes a commitment from the Ruiz Group, which specialises in urban bus transport, support from the Seur Group, a leading Spanish logistics company that has undertaken an ambitious process of decarbonising its fleet, and involvement from the municipal waste collection company Getafe LYMA and the cash-in-transit company LOOMIS.

MRG will also use this project to bring about a progressive transformation of its fleet of vehicles powered by renewable hydrogen.

Renewable Hydrogen Valley project in the Region of Madrid

The Renewable Hydrogen Valley is a project in the Region of Madrid to deploy a large-scale renewable hydrogen solution consisting of an electrolysis plant with a maximum capacity of 60 MW, which will be fed by a photovoltaic solar energy facility.

The hydrogen produced will be used mainly to decarbonise the Adolfo Suárez Madrid-Barajas airport by replacing natural gas with green hydrogen from the existing cogeneration plant, helping to meet the airport’s energy needs. It will also be used for fuel cells to power the machinery used in airports and loading terminals for goods and passenger handling, replacing the energy they currently consume with power from renewable hydrogen.

Part of the energy produced will also be used to support the pre-industrialisation process of aircraft prototypes powered by renewable hydrogen, through AIRBUS.

The project will be located in the Henares Corridor, an ideal location in which to develop economic activities, particularly those with links to transport and logistics. Its location along the Madrid-Zaragoza-Barcelona axis means it is on the route for goods coming in from elsewhere in Europe.

This axis is the most important logistical enclave in the region, as it includes Madrid-Barajas airport, one of the most important infrastructures and transport hubs in the region, as the largest Spanish airport in terms of passengers, air cargo and number of operations.

Several hydrogen distribution points will also be installed in the Henares Corridor area, which will be used to supply the energy needs for hydrogen-powered mobility, mainly in relation to urban transport and for medium and long distance heavy goods transport.

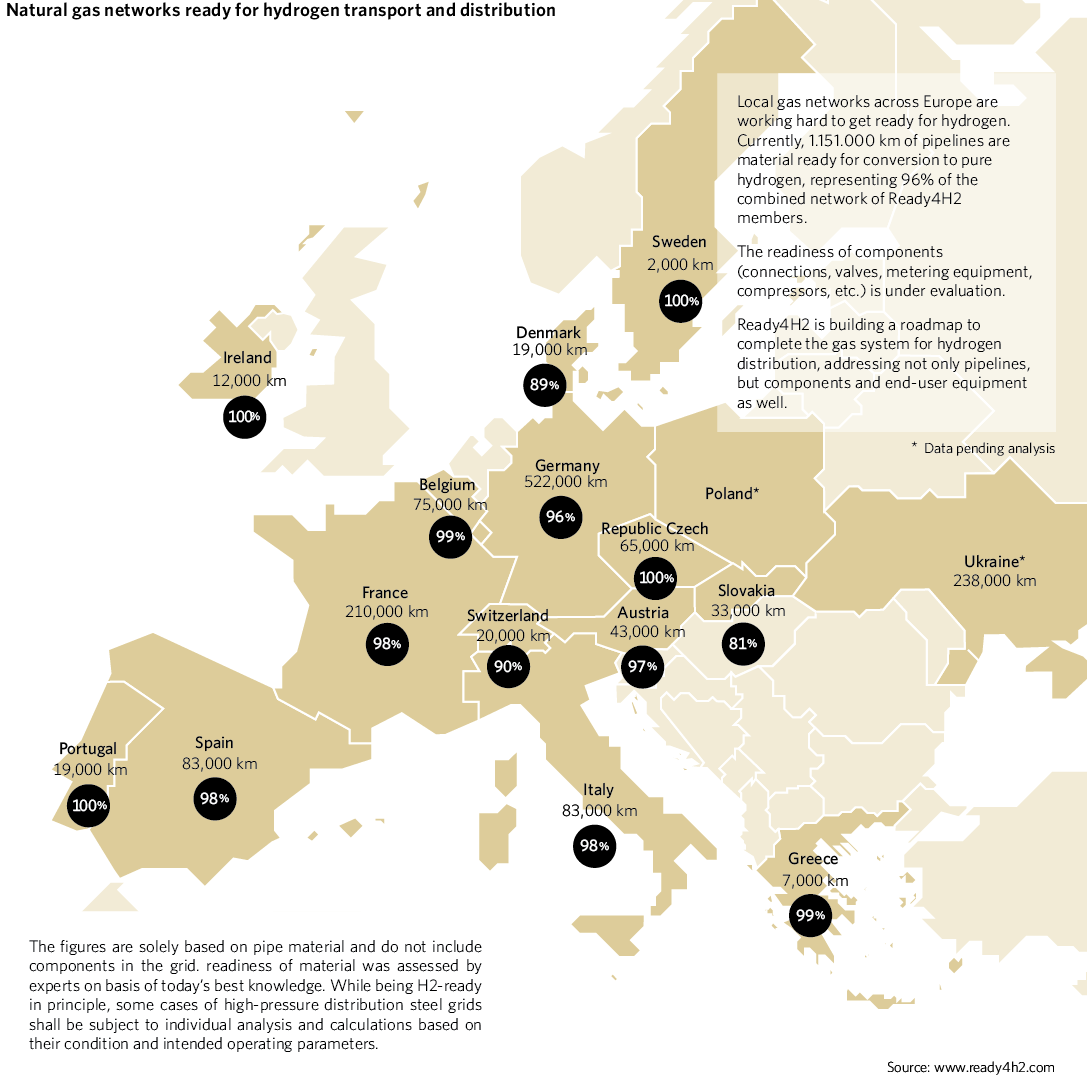

We form part of the “Ready4H2” European hydrogen challenge.

Madrileña Red de Gas is working jointly with the other gas distribution companies in Spain (Nedgia, Redexis, Nortegas and Gas Extremadura) to ensure that the knowledge and experience gained individually in their own projects and in collaboration with other local actors in the hydrogen sector is gathered together and compiled so that it may be of use to those with responsibility in drafting Spanish and European energy policy. The aim is to implement a regulatory framework for developing hydrogen that can harness the potential of the European gas infrastructure, and thus benefit citizens and help meet the target of climate neutrality.

‘Ready4H2’ is focusing its work on three studies. The first of these analyses the various distributors’ involvement in developing hydrogen, the accumulated experience and the strategy adopted in different countries. This included examining how the different official bodies are involved in developing hydrogen and up to what point the hydrogen strategy has evolved in each country.

The second study, on how European gas distributors can help in developing hydrogen and in strategic planning for the region, analyses each distributor’s experiences and knowledge, as well as the position of the various gas distribution companies and their contribution to strategic planning for the region.

The third analysis sets out a road map with specific initiatives so that gas distributors can form the link between hydrogen producers and consumers, both nationally and at the European level.

As the first company in the Iberian Peninsula to operate a distribution network that is completely independent from the rest of the gas companies, we are proud to announce our involvement in the project that will help hydrogen supply networks to evolve and bring about environmental improvements.

5.2.5 Waste

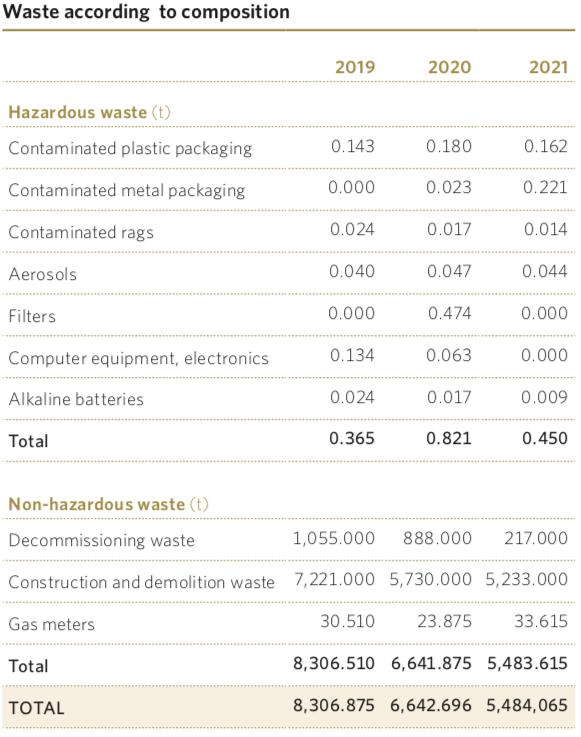

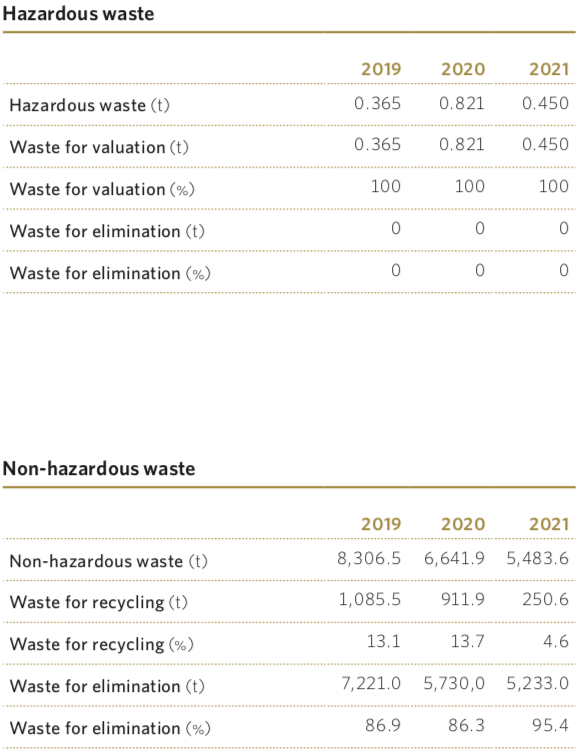

Madrileña Red de Gas has specific procedures in place for managing its waste, with criteria for waste generated in the workplace, in logistics centres and in industrial facilities such as regulating and metering stations (RMSs), liquefied natural gas (LPG) plants and liquefied petroleum gas (LPG) plants.

Whenever possible, actions taken are focused on:

- Applying techniques and alternatives to prevent waste being generated.

- Reduction at source of the amount of waste generated.

- Finding internal or external ways to add value to waste (reuse or recycle).

Temporary storage of waste in Madrileña Red de Gas facilities is done in a controlled manner, particularly waste that could be at risk of degrading the local environment. Recyclable waste such as meters are separated into aluminium and scrap metal. Metal materials with value are segregated and separated from one another, and the different scrap metals obtained are grouped together by material and characteristics, for easier transportation to foundries where they can be processed.

What happens to the waste that occurs from dismantling LPG plants logically depends on how many are taken down. MRG dismantled 130 plants in 2019, 118 plants in 2020 and 37 plants in 2021, working in coordination with the local authorities in the various municipalities involved, which consisted of emptying out, burning, rendering inert and removing 52 tanks. This required more than 50 journeys to transfer the emptied gas to other MRG plants, ensuring none of it was released into atmosphere, and transporting the waste obtained from the dismantling process to processing plants run by the Madrid region authorities, while complying with MRG’s environmental commitment, and all without disturbing the usual activities of our customers and their neighbours, with all precautions taken and with COVID-19 disinfection protocols performed during and after each job, so that the area was always completely disinfected once the work had been completed.

During the dismantling process, under the supervision of the executive works manager, the waste management plans of contractor companies are exhaustively checked and all the documentation relating to waste managed is gathered.

In this regard, in terms of how waste is managed, whenever possible:

- The earth moved when dismantling LPG tanks is reused.

- The terrain is reset with material and earth of similar characteristics to those of the surrounding area.

- Materials that can be reused (which may be the case of vaporisers, extinguishers or regulators) are transported to MRG storage sites.

- Tanks are collected by a recycling company.

- Part of the trench where underground tanks were installed is covered with building and demolition waste, reused as backfill, which is then covered over with new earth.

- Building and demolition waste is collected by a certified waste management company to be taken to waste disposal facilities.

The percentage of recycled waste dropped in 2021 as the number of dismantled LPG plants was much lower than in previous years.

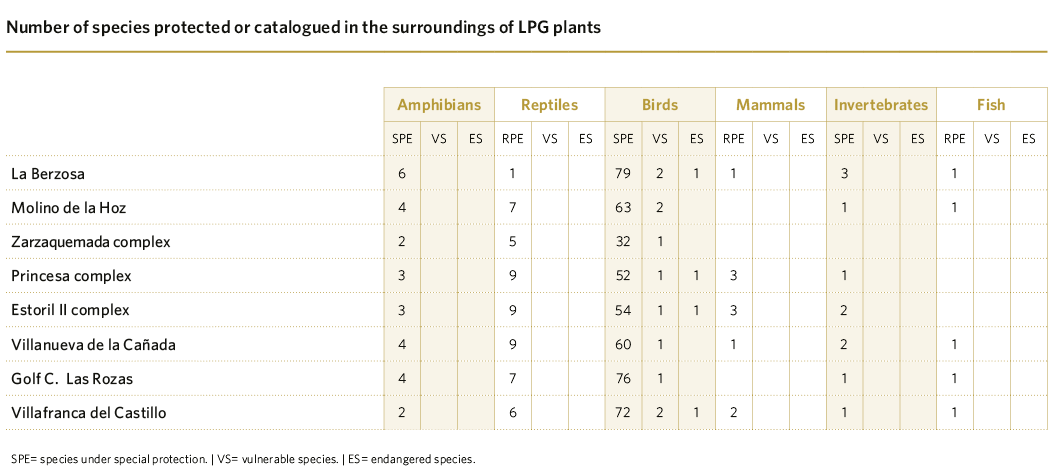

5.3 Biodiversity

Madrileña Red de Gas has very few facilities in nature reserves or areas of high ecological value; in general, MRG facilities are in urban locations, although it is inevitable that a small number are located in areas of this kind, or close to them, given our mission of ensuring gas and therefore energy can reach wherever it is needed.

We currently have 154 LPG satellite plants and five LNG plants that supply homes in place that the distribution network does not reach. As of the end of 2021, 13 LPG plants are located in nature reserves or areas of high environmental value, and no LNG plants at all in any such areas. Specifically, 12 are located inside the Manzanares River Upper Basin Regional Park, and one in the Guadarrama River Middle Course Regional Park and surrounding area.

In terms of our distribution network, we have 6,215 km of natural gas pipeline in the Madrid region, with 206 regulation and metering stations (RMSs), of which ten are in nature reserves, specifically eight are in the Manzanares Upper Basin park and two are in the Guadarrama Middle Course park and surrounding area.

As part of our commitment to biodiversity once the facilities located in or next to nature reserves have been identified, we analysed and assessed the possible risks to determine the courses of action that needed to be taken

For facilities located in these nature reserves, the inventory of habitats of regional interest was carried out using the GEOPORTAL MAPAMA tool from the Ministry of Agriculture, Fisheries and Food. The same procedure was performed for facilities located in areas adjacent to these nature reserves. The priority habitats inventoried at these facilities are:

- Pseudo-steppe with grasses and annuals of the Thero-Brachypodietea (habitat code 6220)

- Mediterranean temporary ponds (code 3170)

- Endemic forests with Juniperus spp. (code 9560)

Species were also identified that appear on the IUCN Red List, recording the categories of the different species identified: specially protected species, vulnerable species (VU) and endangered species (EN). In general terms, the issue is one of species in special protection, particularly birds. There are very few cases of vulnerable species and endangered species.

The aforementioned facilities are affected by Law 26/2007 of 23 October on Environmental Responsibility and all necessary administrative procedures have been followed, with specific financial guarantees required for three of these facilities, at Villafranca del Castillo, La Berzosa and Villanueva de la Cañada.

As part of our commitment to biodiversity and in compliance with current legislation once the facilities located in or next to nature reserves have been identified, we analysed and assessed the possible risks to determine the courses of action that needed to be taken.

Adhering to our working methodology, at MRG we identified the aspects and impacts on the environment resulting from the presence of its facilities in various stages (construction, maintenance, possible modification and dismantling), assessing the risks and applying the necessary protection or mitigation measures as appropriate.

The maintenance work that regulation and metering stations are subject to includes applying weed killer to eliminate plant elements that could pose a risk to the safety of the facility, and thus also to its surrounding area. The use of these products is regulated by Royal Decree 1311/2012, of 14 September, establishing the framework of actions to be taken to ensure the sustainable use of phytosanitary products. MRG meets all the requirements. Prior to applying any such products, authorisation must be sought from the appropriate local authorities. In the case of facilities located within nature reserves, the advisory document that accompanies the application makes specific mention of priority in the use of low-risk phytosanitary products. The documentation is also sent to the managers of the nature reserve, specifically the director of the Manzanares Upper Basin Regional Park or of the Guadarrama River Middle Course Regional Park and surrounding environment.

LPG facilities are subject to periodic maintenance activities, which include clearing out the enclosures where they are located, and re-stamping every 15 years in accordance with applicable legislation (Royal Decree 919/2006, of 28 July).

The purpose of the clearing out work is to remove elements of vegetation that could pose a risk to the safety of the facility. Manual methods tend to be used in the facility’s ATEX zone, and mechanical methods (brush cutter) are used for the rest of the facility. In terms of re-stamping, the residual gas in the tank is removed and burned.

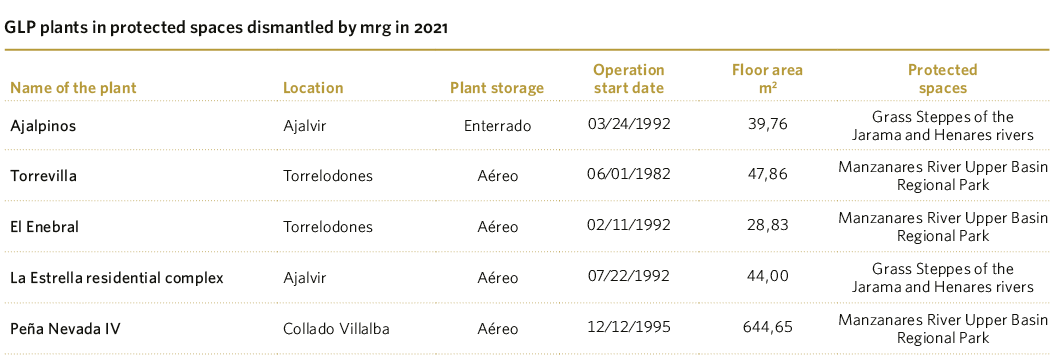

In 2021 we dismantled five LPG plants located in these important areas of nature, i.e. we reduced the number of LPG facilities in nature reserves or areas of high ecological value by 28%

For satellite plants that are on forest land or in an area of 400m around any such land, authorisation must be sought from the Directorate-General of Civil Protection. As well as all the measures in place to prevent accidents, the application also includes full details of the fire extinction equipment available during these works.

As part of the preventive measures implemented, it should be stated that a safety officer will always be present with verified communication to Madrid’s 112 emergency helpline to report any possible incidents. This officer will proceed to halt any work immediately if the meteorological circumstances or the vegetation conditions were such that they posed a risk of starting a forest fire.

Machinery and equipment is always fitted with devices to prevent explosions, sparks and/or electrical discharges from occurring. The machinery and equipment used has undergone appropriate cleaning and maintenance to ensure it is fully operative.

It should be pointed out that in 2021 we dismantled five LPG plants located in these important areas of nature, i.e. we reduced the number of LPG facilities in nature reserves or areas of high ecological value by 28%, leading to 805 m2 of land being recovered. Three plants are located in the Manzanares River Upper Basin Regional Park, and two are in the Special Protection Area for Birds: Grass Steppes of the Jarama and Henares rivers.

In this regard, year on year we try to dismantle LPG plants by restoring the areas occupied by satellite plants and finding alternatives so as not to occupy new land.

All building activity, in this case dismantling work, has a site manager assigned by MRG, who is responsible for approving the waste management plan before any construction and demolition work is carried out by the contractor hired for this purpose, and for signing off the works completion certificate.

MRG hires an external company to gather data, and samples where appropriate, to write up the mandatory contaminated soils closing report. These reports are submitted to the appropriate authority in the Region of Madrid, which then issues an administrative ruling on the matter.